①High-quality bending process

The state-of-the-art press brake introduced. It equips with angle sensors to measure force and bending angle during forming in consideration of the springback.Measure an angle of product after bending process is done, angle correction value is automatically calculated and accurately performs the run-in process by equipped digital setting.

②High-quality bending process

The hydraulic cylinders located in the lower beam of the machine automatically compensates for any ram deflection and crowning system is able to detect real force and compensates the deflection.Automatic selection of bending machine tools by CAM and achieve shorter delivery time by the function of the sequence calculation of automated bending process.

Robotic fiber optic laser welding

The next generation of welding technology "fiber laser welding" introduced. Capable of welding highly reflective materials and hard materials such as aluminum and copper because of a short wavelength and high beam absorption against the materials. Consequently it achieves high airtight with a continuous wave and smooth high-quality welding.

Tapping

In-house tap process is also available.At the time of your order, we will undertake cutting, bending and welding together.

|

Fiber laser welding system

|

|

Model : FLW-6000 6-axis articulated robot

Maker : AMADA CO., LTD.

Cutting capacity

sheet thickness : SUS 9t, Al 6t

Positioning accuracy : ±0.07mm

Robot carriage length : 6,000mm

Maximum process range

X direction : 1,000 ~ 1,900mm

Z direction : 500 ~ 1,300mm

Y direction : -1,530 ~ 7,600mm

|

New!!

Introduced in December 2015

Video Video

|

|

|

|

Bending Machines 2200kN

|

|

Model : HG2204

Maker : AMADA CO., LTD.

Cutting capacity

Pressure capability : 2200kN

Bending length : 4,300mm

Stroke length : 250mm

New hybrid drive system

and hydraulic crowning system

New backgauge system

Angle sensor

|

Introduced in September 2014

|

|

|

|

Bending Machines 600kN

|

|

Model : EG6013

Maker : AMADA CO., LTD.

Cutting capacity

Pressure capability : 600kN

Bending length : 1,350mm

Stroke length : 150mm

New backgauge system

Angle sensor

|

Introduced in February 2015

|

|

|

|

Double-Column Machining Centers

|

|

Model : MCV20A

Maker : OKUMA

Cutting capacity

Table : (W) 1,300mm x (L) 3,800mm

Effective width : (W) 2,050mm x (H) 1,500mm(max)

|

|

|

|

Bevel Cutting Machines

|

|

Model : VXW-4005-5

Maker : SHINX

Cutting capacity

sheet thickness : 8mm ~ 60mm

Maximum length 4,000mm

|

|

|

|

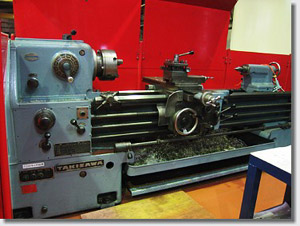

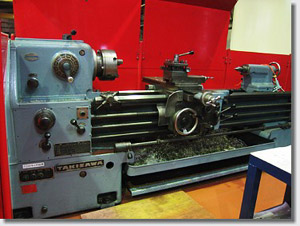

Engine lathe

|

|

Model : TAL460

Maker : TAKIZAWA TEKKO

Cutting capacity

dia.250 x length 1500

|

|

|

|

Tapping

|

|

Model : QUICKTAP

Maker : HOTAS

Cutting capacity

Maximum sheet thickness : 10t

M3 ~ M10

|

|

|

|

Straightening Press

|

|

Model : KS-MR100T-101

Maker : KISO SEIKI

Cutting capacity

Maximum sheet thickness : 50mm width : 2,600mm

Pressure capability : 100kN

|

|

|

|

Camber adjustment

|

|

Model : HAT50-01

Maker : KAZUKI KOGYO

Cutting capacity

Sheet thickness : 10mm ~ 65mm

width 250mm x length 6,000mm

|

|

|

Stainless steel, Aluminum, Copper, Titanium, etc.

Stainless steel, Aluminum, Copper, Titanium, etc.